ACHIZIȚIA DATELOR

IN LabVIEW II

1. Obiectivele

lucrarii

a) To learn how to use

LabVIEW for analog input through a DAQ card.

b) To learn about Analog to

Digital conversion and how to acquire a signal and display it in LabVIEW.

c) To study the effect of

the sampling frequency in analog to digital conversion.

In this

experiment, you will write a LabVIEW VI to acquire an analog signal from the

analog input pins of the NI ELVIS, display it in LabVIEW, and calculate its RMS

and average values.

You will also

show the relationship of amplitude to number of averages. This lab requires background

in analog to digital conversion and the concepts of sampling and Nyquist

sampling theorem.

2.Aparatura si suporturile utilizate:

a) PC in configuratia unitate

centrala,monitor, tastatura;

b) NI ELVIS

c) Precizarile din prezentul

indrumar;

d) Manual de prezentare a mediului de

programare grafic LabVIEW.

3.Breviar

In 1928, H.

Nyquist showed that an analog signal could be perfectly reconstructed solely

from its sample values. This could be done without any loss of its original

information if the sampling rate is at least twice the bandwidth of the signal,

thus the famous rule:

Nyquist

sampling rate = 2 x signal bandwidth

For example, a

signal with a bandwidth of 1000Hz must be sampled at 2000 or more

samples/second without any loss of information.

Figure

1. Sine and cosine waves sampled at twice the signal frequency

Sampling at

exactly twice the signal frequency is not enough in most practical situations.

Figure1 illustrates this problem and it is a common practice to use a sampling

rate as much as 10 times the signal bandwidth is used when doing an anolog to

digital conversion.

Figure

2. Adequately sampled

signal and under sampled signal.

Quantization

Errors

The term

quantization error (or quantization noise) is used to describe the fact that a

digital value can correspond to a distinct span of analog signals. Any analog

signal within the zone of one LSB will have the same digital value and

therefore look identical to all others after the analog-to-digital process. It

is this small degree of error in misrepresentation that is known as

quantization error. In order to closely reconstruct the original analog signal,

the analog to digital conversion process needs to minimize the quantization

error as much as possible. To reduce the quantization error, more divisions

(higher resolution) should be used to represent the analog value.

Data Acquisition

using LabVIEW

As shown in the

figure above, LabVIEW initiates a DAQ operation by calling NI-DAQ which

contains the drivers for the board, i.e. signals the hardware to initiate the

I/O operation. DAQ boards use on-board buffers and RAM buffers as an

intermediate place to store the data they acquire. Also hardware can be used to

initiate the I/O operation, which is called a triggering.

Two important

steps will help to classify the type of DAQ operation:

. Whether you

use a buffer

. Whether you

use an external trigger to start, stop, or synchronize an operation

A Buffer is

an area of memory reserved as a temporary location for data. For fast data

acquisition, the DAQ board stores the data into a buffer immediately after

acquisition, so that it may be retrieved later for display or analysis. When

the PC memory is used for the buffer, it is called a DMA (Direct Memory Access)

operation. It is recommended to use the buffered I/O when you need sample more

than 10 samples per second. Nonbuffered I/O can be used for slow signals and

also reduces memory overhead for the PC.

Triggering

Triggering

refers to any method by which you initiate, terminate, or synchronize a DAQ

event. A trigger is usually a digital or analog signal whose condition is

analyzed to determine the course of action.

Software

Triggering is the

easiest and most intuitive way to do it-you control the trigger directly from software,

such as using a Boolean front panel control to start/stop data acquisition.

. The user

needs to have explicit control over all DAQ operation

. Timing of the

events needn't be very precise

Hardware

Triggering lets the

circuitry in the board take care of the triggers, adding much more precision and

control over the timing of your DAQ events. Hardware triggering can be further

subdivided into external and internal triggering. An example of an internal

trigger is to program the board to output a digit pulse when an analog-in

channel reaches a certain voltage level. An example of an external trigger is

to have the board wait for a digital pulse from an external instrument before

initiating an acquisition. Many instruments provide a digital output (or

"trigger output") for this purpose.

. Timing a DAQ

event needs to be very precise

. Need to

reduce the software overhead

. DAQ events

must be synchronized with an external device.

Functions in

NI-DAQmx.

All the

functions related to the data acquisition are accessed through NI DAQmx palette

located at Functions>> Measurements I/O.

1. DAQ

Assistant.

DAQ Assistant

is a graphical interface for interactively creating, editing, and running

NI-DAQmx virtual channels and tasks. An NI-DAQmx virtual channel consists of a

physical channel on a DAQ device and the configuration information for this

physical channel, such as input range and custom scaling. An NI-DAQmx task is a

collection of virtual channels, timing and triggering information, and other

properties regarding the acquisition or generation.

2. NI-DAQmx

Create Virtual Channel.

The NI-DAQmx

Create Virtual Channel function creates a virtual channel and adds it to a

task. It can also be used to create multiple virtual channels and add all of

them to a task. When a task is not specified, the function creates a task. The

NI-DAQmx Create Virtual Channel function has numerous instances. These

instances correspond to the specific type of measurement or generation the

virtual channel(s) perform.

3. NI-DAQmx

Timing.

The NI-DAQmx

Timing function configures the timing for hardware-timed data acquisition

operations. This includes specifying whether the operation will be continuous

or finite, selecting the number of samples to acquire or generate for finite

operations, and creating a buffer when needed.

4. NI-DAQmx

Start Task.

The NI-DAQmx

Start Task function explicitly transitions a task to the running state. In the

running state, the task performs the specified acquisition or generation. A

task will be implicitly transitioned to the running state, or automatically

started, if the NI-DAQmx Start Task function is not used, when the NI-DAQmx

Read function executes. This implicit transition also occurs if the NI-DAQmx

Start Task function is not used and the NI-DAQmx Write function executes with

its auto start input specified accordingly.

5. NI-DAQmx

Read.

The NI-DAQmx

Read function reads samples from the specified acquisition task. The different

instances of the function allow for the type of acquisition (analog, digital,

or counter), the number of virtual channels, the number of samples, and the

data type to be selected.

6. NI-DAQmx

Write.

The NI-DAQmx

Write function writes samples to the specified generation task. The different instances

of the functionallow for the type of generation (analog or digital), the number

of virtual

channels, the

number of samples, and the data type to be selected.

7. NI-DAQmx

Clear Task

The NI-DAQmx

Clear Task function clears the specified task. If the task is currently

running, the function first stops thetask and then releases all of its

resources. Once a task has been cleared, it cannot be used unless it is recreated.

Thus, if a task will be used again, the NI-DAQmx Stop Task function should be

used to stop the task, but not clear it.

4. Mod de lucru

a) Se alimenteaza sistemul

cu tensiune;

b) Se lanseaza mediul LabVIEW;

c) Se implementeaza programele descrise mai jos.

4.1 Acquire

Analog Input.

Objective: To use DAQ Assistant.vi to acquire analog

input.

1. On the NI

ELVIS protoboard connect the function generator output to channel ACH0+

and the Ground to ACH0-.

2. Switch on

the power supply for NI ELVIS station (Switch located on the back of the ELVIS

station).

3. Switch on

the power supply for prototyping board. Make sure that the three LED's on

the prototyping board are on.

4. On the NI-ELVIS

station front panel, in the function generator section change the

switch to

manual mode and select sinusoidal function.

5. Open a blank

vi and place the DAQ Assistant.VI located on the Function >>

Measurement I/O >>DAQmx palette on the block diagram.

6. A DAQ Assist

dialog box appears to help you configure the measurement task as shown in the

figure below.

7. Select acquire

signals >> analog input >> Voltage to create new voltage

analog input task.

8. The dialog

box then displays the list of channels on DAQ device installed. The number of

channels listed depends on the number of channels on the DAQ device. Select ai0

and click the finish button.

9. As shown in

figure below, a dialog box opens to configure the selected channel. Keep the

default settings for the signal input range, timing.

10. To check

whether channel is configured properly, click the run button locate on the top

left corner of the dialog box. Click OK on the dialog box to return to

the block diagram.

11. On the

block diagram, right click the data output on the DAQ Assistant and

select Create>> Graph Indicator.

12. Create rate

and number of samples controls for the DAQ Assistant.vi as

shown in the figure below.

13. On the NI

ELVIS front panel, in the function generator section, keep the

coarse frequency knob at 50Hz and fine frequency and amplitude

at the maximum value.

14. Save the VI

in your section's folder as "<lastname>_Analog Input.vi".

15. Run the VI

using rate 1000 Hz and number of samples 50, 100, 200 and 1000.

Notice the change in the time scale of the graph indicator when you

change the number of samples.

16. Keeping the

number of samples at 100, change the rate to 25, 50, 100, 500 and

1000. Notice change in the display of Graph Indicator.

17. Close the

VI.

4.2.

Statistical Analysis of the Analog Input

Objectives:

To analyze the analog input using Statistics .vi and understand the effect of

sampling rate.

1. Open the

"<lastname>_Analog Input.vi

2. Select the Statistics

Express VI from the Express>>SignalAnalysis sub palette of the

Functions palette and place it on your Block Diagram.

3. Keep the number

of samples at 200 and rate at 1000 Hz.

4. Wire the

data Ouput of the DAQ Assist VI to Signal input of Statistics

VI.

5. Right-click

the Arithmetic Mean output of the Statistics VI and select Create»Numeric

Indicator. This will create a numeric indicator on the Front Panel that

will display the Arithmetic mean. Repeat this step for the Maximum, Minimum

and RMS outputs of the Statistics VI.

6. Right click

on the block diagram and select Merge Signals from Express>>

Signal Manipulation.

7. Right-click

on the block diagram and select Express» Output» Write to Measurement

File.

8. Configure

the Write to Measurement as shown below.

9. Connect the Mean,

Maximum, Minimum and RMS outputs of Statistics Express VI to Merge

Signals and Connect the Merge Signal output to Write To

Measurement express vi as shown in the figure below.

10. Save the VI

in your section's folder as "<lastname>_SignalAnalysis.vi". Run the VI by

keeping number of samples at 200 and change the rate to 25, 50,

100,250 an 500 Hz. Fix the X-scale of the wave form graph to 0 to 0.2 sec.

Discuss the results in your report?.

11. Open the analysisData1.lvm

located in ME337L_F08/sec00# and make sure that data for each case is

saved in the file.

12. Use

excel to plot the data you have collected. Report the data as shown in the

figure below.

13. Save the VI

and exit.

4.3.

Acquiring Multiple Analog Inputs

Objective:

To use the DAQmx Data Acquisition Palette

1. On the NI

ELVIS proto board connect the function generator output to channel ACH0+

and the Ground to ACH0- and connect the +5VDC to ACH1+

and the Ground to ACH1-.

2. Open a blank

vi.

Select DAQmx Create virtual channel.vi located

in Functions>> Measurement I/O>> NI-DAQmx palette .

4. Right click

on the physical channel terminal and select create from the

shortcut menu and select constant. From the drop down menu of the

constant, select Dev1/ai0, as shown in the figure below.

Change the

content of this constant to include channel 1 as shown

5. Right click

on the Minimum and Maximum values terminals of the DAQmx

Create virtual channel.vi to create controls .

6. Select Timing

.vi. located in Functions>> Measurement I/O>> NI-DAQmx

palette. This VI specifies the timing of the acquisition.

7. Connect the

error out and task out terminals of the Create virtual channel vi to the

corresponding terminals of Timing.vi.

8. Create

controls in the Rate and Samples per channel terminals of the Timing

vi and a constant in its Sample mode terminal.

9. Select Start

Task .vi. and DAQmx Read vi located in Functions>>

Measurement I/O>> NI-DAQmx palette. Connect the error out and task

out terminals of these two vi's.

10. Select the

drop down menu from the DAQmx Read vi and select Analog>>Multiple

Channels>>Multiple Samples>>1D Waveform, as shown below.

11. Create an indicator

in the Data terminal of the DAQmx Read vi .

12. Select Clear

Task .vi located in Functions>> Measurement I/O>> NI-DAQmx

palette. Connect the error out and task out terminals of the DAQmx Read

vi to Clear Task .vi

13. Add a Simple

Error Handler vi located in Functions>>Dialogue and User Interface

palette and connect it to the error out of the Clear Task .vi.

14. In the

front panel, change the representation of Data from Cluster to Waveform

Graph.

15. Save the VI

in your section's folder as "<lastname>_Multiple_Channels.vi".

16. Set the

Sample per channel to 100 and the rate to 1000 and Run the vi and report the

results.

17. To sample

the input continuously, change the Sample mode of the Timing VI to

Continuous Samples.

18. Include the

DAQmx Read vi and the Data Waveform in a While loop. Add a

control to stop the loop.

19. In the No

of samples per channel terminal of the DAQmx Read vi, add a control

and set its value to 100.

20. Save the VI

in your section's folder as "<lastname>_Multiple_Channels_Cont.vi".

21. Run the vi

and include the results in your report.

22. Close the

vi.

Voltmeter VI

In this exercise, the objective is to acquire an analog signal using

a DAQ device. Complete the following steps to build a VI that measures the

voltage that the temperature sensor on the DAQ Signal Accessory outputs. The

temperature sensor outputs a voltage proportional to the temperature. The

sensor is hard-wired to channel 0 of the DAQ device.

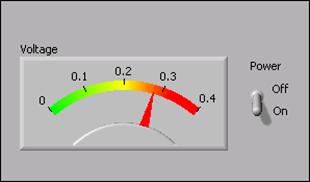

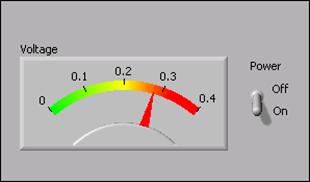

Front Panel

- Open a blank VI and build the front panel shown in figure 1.

|

Figure 1

|

- Place

the

Meter, located on the Controls>>Numeric Indicators palette,

on the front panel. Configure the meter scale for to . Use the

Labeling tool to double-click and type . You

might need to enlarge the meter to display the scale as shown in the example.

- Place a

Vertical Toggle

Switch, located on the Controls>>Buttons & Switches palette, on the front panel. Configure the toggle switch to a

default value of False and a mechanical action of Latch When Pressed

- Create

two free labels,

Off and On, using the Labeling tool.

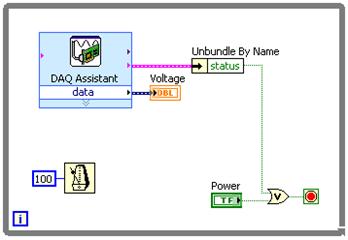

Block Diagram

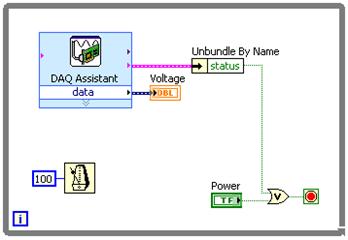

- Build the block diagram shown in figure 2.

|

Figure 2

|

Place

the

Place

the DAQ Assistant Express VI located on the Functions>>Input palette, on the block diagram. Configure this VI to read an analog input

channel and return the voltage.

- Select

Analog

Input>>Voltage for the measurement to

make.

- Select

Dev1>>ai0 for the physical channel.

- Click the

Finish button.

- The

Analog

Input Voltage Task dialog box appears.

Configure the Task

Timing to Acquire 1 Sample

- Click the

OK button to close the Analog Input Voltage Task Configuration dialog box. This saves the settings specified for the task in

the DAQ Assistant

Express VI.

Place

the

Place

the Wait Until Next

ms Multiple function, located on the Functions>>All

Functions>>Time & Dialog palette,

on the block diagram. Right-click the input and select Create Constant from the shortcut menu. Type in the constant

to cause the loop to execute every 100 ms.  Place

the

Place

the Unbundle by Name function, located on the Functions>>All Functions>>Cluster palette, on the block diagram. Use this function to access the status from

the error cluster.  Place

the

Place

the Or function, located on the Functions>>Arithmetic &

Comparison>>Express Boolean palette, on

the block diagram. This function stops the loop if an error occurs or the

user clicks the power switch on the front panel.

- Save the VI as

Voltmeter.vi in the C:ExercisesLabVIEW

Basics I directory. You will use this VI later

in the course.

- Display the front panel and run the VI. The meter displays the

voltage the temperature sensor outputs. Place your finger on the

temperature sensor and notice that the voltage increases.

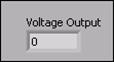

4.5. Voltage Output VI

In this exercise,

the objective is to output an analog voltage using a DAQ device. Complete the

following steps to finish a VI that outputs voltage from 0 to 9.5 V in 0.5 V

steps.

- Connect Analog Out CH0 to Analog In CH1 on the DAQ Signal

Accessory.

Front Panel

- The front panel is already built.

|

Figure 1

|

Voltage

Output displays the current voltage output.

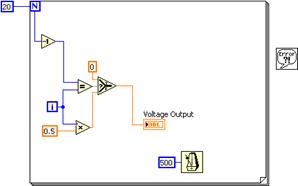

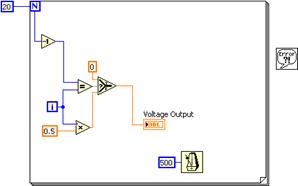

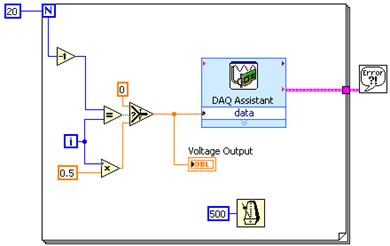

1.b) Block Diagram

- Display and examine the block diagram.

|

Figure 2

|

The

The

Wait Until Next ms Multiple function

located on the Functions>>All Functions>>Time

& Dialog palette causes the For

Loop to execute every 500 ms.  The

The

Select VI located on the Functions>>Arithmetic

& Comparison>>Express Comparison

palette checks if the loop is in its last iteration. If the loop is in

its last iteration, then the DAQ device outputs 0 volts. This is a good

technique to reset the output voltage to a known level. It is always a

good idea to reset the output voltage to something that will not damage a

device that is connected to the DAQ device.

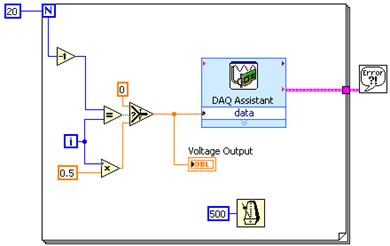

- Modify the block diagram as shown in figure

|

Figure 3

|

Place

the

Place

the DAQ Assistant

Express VI, located on the Functions>>Output palette, in the For Loop.

Complete the following steps to configure this Express VI to generate an

analog output voltage.

a.

Select Analog

Output>>Voltage for the measurement to make.

b.

Select Dev1>>ao0 for the physical channel and click the Finish button.

c.

In the Analog Output

Voltage Task Configuration dialog box that appears,

configure the Task Timing to Generate 1

Sample. Change the output range minimum to and maximum to

d.

Click the OK button to close the Analog Output Voltage Task Configuration dialog box. This saves the settings specified for the task in the DAQ

Assistant Express VI

- Save the VI.

- Close the block diagram but leave the front panel open.