Manipulation of nanoparticles

within a microfluidic system based on SU-8 polymer for bio-applications

CONTENTS

INTRODUCTON

FABRICATION

2.1. Microfluidic device

2.2. Preparation of solutions with magnetite nanoparticles

3.

CHARACTERIZATION

3.1. Characterization of the

magnetite samples

3.2. Characterization of the

microfluidic device

4. Simulation of fluid flow through the

microchannel

5. Conclusions

ABSTRACT

We present in this paper experimental results regarding

the control the fluid flow of aqua solution whit different nanoparticles such

as magnetite - Fe3O4, magnetite Fe3O4

- functionalized with silver particles, Fe3O4-functionalized

with gold particles, and gold nanoparticles by an array of Cr/Au electrodes in

a microfluidic system. The crystals of magnetite nanoparticles used in this

experiment, with particle size in the range of 10 nm, were synthesized by the

coprecipitation method from an aqueous Fe3+/Fe2+

solution. The microfluidic system was fabricated using SU-8 polymer and it

consists of an inlet, an outlet and a microfluidic channel with width of 200µm

control and length of 8250µm. The electrodes were configured on the bottom of

the microchannel. They are used to apply a small voltage on the solution in the

microchannel. The microfluidic system was characterized by optical microscopy,

white light interferometry and SEM (scanning electron microscope). We simulate

the distribution of the fluid velocity in the channel and we study the movement

of aqua solutions with different nanoparticles in the microfluidic system under

the influence of different voltages were applied, with different polarities.

1. INTRODUCTON

The use of

magnetic particles for isolation and preparation of bio-cells and proteins is

considered to be great interest in bioscience . The magnetite nanoparticles are attractive materials for

application in biomedical area such as diagnostic techniques, drugs, and

prostheses and implants. Interest is booming in biomedical applications for use

of nanoparticles in cell therapy (marking cells), cell biology (separation and

purification of cells populations), tissue repair, drug transport to the

affected area, and magnetic resonance . Among them, the magnetite (Fe3O4)

is one of the most suitable magnetic materials for bio-applications because it

has demonstrated a low toxicity and it is well tolerated by the human body. The

magnetite (Fe3O4) has an inverse spinel cube structure.

The oxygen atoms form a closed packing and iron cations occupy tetrahedron or

octahedral interstitial positions. Electrons can jump between ions Fe2+ and

Fe3+ in octahedral positions at room temperature [2-4]. The magnetite

nanoparticles were functionalized before being embedded with gold and silver.

In the aqueous solutions have been introduced different nanoparticles:

magnetite (Fe3O4), Fe3O4-Ag, Fe3O4-Au,

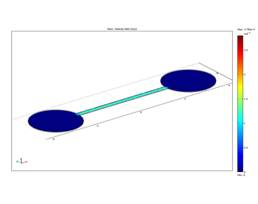

and gold nanoparticle. We simulated the liquid flow within the microchannel

using COMSOL multiphysics software, in order to determine the fluid velocity,

therefore the minimum debit of the microfluidic system. The flow was considered

to be laminar and incompressible. There were calculated the velocity and the

flux of the fluid flow under a pressure gradient of 20 Pa from the entrance

reservoir to the exit reservoir. The electrical behavior of the magnetite

samples under the influence of electric field produced by the electrodes inside

the microchannel was measured using an oscilloscope.

2.

FABRICATION

2.1.

Microfluidic device

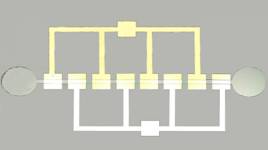

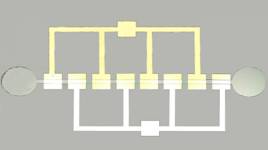

The microfluidic device was fabricated on p type

silicon wafer < >. First, an isolation oxide of 0.5µm layer was

thermally growth. After this, a 200nm thick layer of Cr/Au was deposited by

vacuum evaporation technique on the wafer. The electrodes were patterned using

photolithography and, subsequently, the Cr/Au was etched. The electrode shape

is that of a comb with the fingers (four) interdigitated with the opposite

electrode. The dimension of the electrode is 750µm with a space of 280µm

between them. A 30µm layer of SU-8 2050 polymer was deposited by spinning and

the microchannel with the two reservoirs was pat- terned using UV lithography.

It is well known that it is easy to obtain by lithography SU-8 microchannel

walls with high aspect ratio. In Fig. 1 is presented the fabricated

microfluidic device. The dimension of the reservoirs diameter is 200µm. The

microchannel length is 8520µm and the width is 200µm. These dimensions allows

an easily introduction of the magnetite solutions in the inlet reservoir and

the control of the fluids flow inside the microchannel.

Fig.

1. Optical microscope picture of the microfluidic device.

2.2. Preparation of solutions with magnetite

nanoparticles

There is a wide range of methods for synthesizing

simple magnetite nanoparticles and functionalized magnetite nanoparticles with

precious metals such as silver and gold. We prepared for experiment three

solutions:

aqueous solution of magnetite

(Fe3O4) particles;

aqueous solution of Fe3O4-Ag;

aqueous solution of Fe3O4-Au.

The synthesis of magnetite particles was made by mixing

two solutions of FeCl2 and FeCl3 in the molar

concentration of 1:2. After that, droplets of ammonia solution with 1 molar

concentration were added at equal amount of time until it was achieved the

value 10 for pH of the solution. It is important to add constantly the ammonia

solution so the particle size to be uniform. By filtering this solution we

obtained the magnetite particles with dimensions mostly around 10 nm. These

particles were used further after functionalization in all solutions.

The magnetite solution was obtained by mixing magnetite

particles (5 g) with deionized water (10 ml). We used an ultrasonic

functionalized method for fabrication of the samples at temperatures of 80 C,

for 30 min. We functionalized the magnetite nanoparticles by adding

(3-glycidoxypropyl)trimethoxysilane (3GTMO) in aqueous solution. The role of

3GTMO is to serve as a "coupling agent" or "adhesion promoter" between the

magnetite nanoparticles and the features being embedded (gold and silver

particles).

The functionalized solution of magnetite particles (5

g) where mixed with aqueous solution with gold particles (10 ml-the molar

concentration of 1:10). Initially the silver particles were stored in a

solvent. Before using them, it was washed and diluted in deionized water (the

molar concentration of 1:10). The functionalized solution of magnetite

particles (5 g) where mixed with aqueous solution with silver particles (10

ml-the molar concentration of 1:10). Because of their applications in

biomedicine, the magnetic particles must present properties of biocompatibility

and stability in

aqueous

solutions. If the size distribution of the magnetic nanoparticle is very

narrow, an agglomeration of particles appears due to magnetization phenomenon

that occurs frequently in obtaining uniform magnetic fluids [11].

3. CHARACTERIZATION

3.1.

Characterization of the magnetite samples

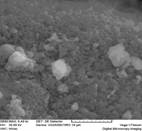

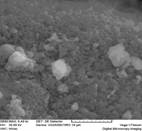

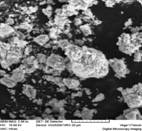

The characterization of simple or functionalized

magnetite samples was performed using the scanning electron microscope SEM. The

aqueous solution with nanoparticles was placed on the glass slide and, after

that placed in a controlled atmosphere, at room temperature to dry out. The

magnetite crystals sizes vary between 0.21 and 4.28µm. In Fig. 2 it can be seen SEM pictures for the other two types of

nanoparticles.

a)

b)

b)  c)

c)

Fig.

2. SEM pictures of the magnetite crystals. (a) Crystals formed by

simple magnetite particles (Fe3O4); (b) crystals of

simple magnetite particles (Fe3O4) functionalized with

gold (Au) particles; (c) crystals of simple magnetite particles (Fe3O4)

functionalized with silver (Ag) particles.

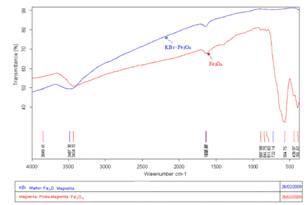

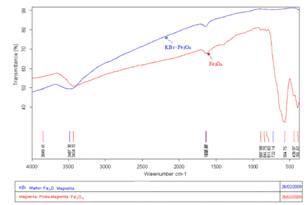

The specific Fourier transform infrared spectroscopy

(FTIR) was done for magnetite particles and FTIR spectra are shown in Fig.

3. The samples for FTIR were prepared by grinding a quantity of the

sample with a specially purified salt (potassium bromide) finely (to remove

scattering effects from large crystals). This powder mixture is then crushed in

amechanical die press to form a translucent pellet through which the beam of

the spectrometer can pass. FTIR spectroscopy highlighted the specific spectrum

of magnetite wavenumber of 391.67 and 554.75cm

Fig. 3. Spectroscopy

FTIR for magnetite particles.

3.2.

Characterization of the microfluidic device.

The microfluidic device was characterized using a white

light interferometer (WLI) resulting the 3D profile of the whole device with

details in the reservoir area and in microchannel area and it is presented in

Fig. 4.WLI is used as a instrument for profilometry by measuring the centre of the axial signal response

from a surface

[12,13]. WLI can measure the position of the surface

to accuracies of up to 1 nm.

a) b)

b)

c)

c)

Fig. 4. 3D profile of the reservoirs and

the microchannel (without magnetite nanoparticles).

The 3D profile obtained by WLI gives the measured

parameters for the microfluidic systems as following: thickness of microchannel

layer is 34µm, reservoirs diameter is 1467µm and microchannel width is 224µm.

These values are in accordance with the designed values. In Fig. 5 are

presented 3D images of the device with the aqueous solution with magnetite

nanoparticles functionalized

with

gold particles. From this figure we determined the size of the simple magnetite

nanoparticles functionalized with gold particles to be 5µm.

a) b)

b)

Fig. 5. 3D

profile of the reservoir and the microchannel with magnetite nanoparticles.

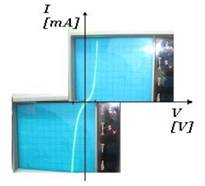

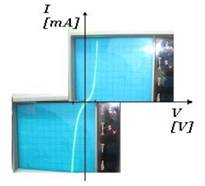

Different voltages were applied on the both electrodes

in order to analyze the behavior of the microfluidic system from electrical

point of view. The metals particles under the action

of an electric field generated by the current circulating in the electrodes

migrated in the aqueous solution in the channel from the inlet reservoir to the

outlet reservoir. If the polarization on the two electrodes is reversed, we

observed the movement of the particles in an opposite direction. Experiments

were realized with solutions containing magnetic particles functionalized with

silver and gold particles. The voltage values varied from 1.5 to 5V. The

particles migration started from 2.5 V. After testing the three types of

solutions, the best result was obtained for aqueous solution with magnetic

particles (Fe3O4) functionalized with gold particles (Au)

and it is represented in Fig. 6 the current-voltage characteristic in direct

and reverse polarization, directly on the oscilloscope screen.

Fig. 6. Current-voltage characteristic of

the device with magnetite nanoparticles.

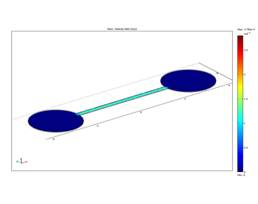

4.

Simulation of fluid flow through the microchannel

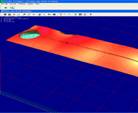

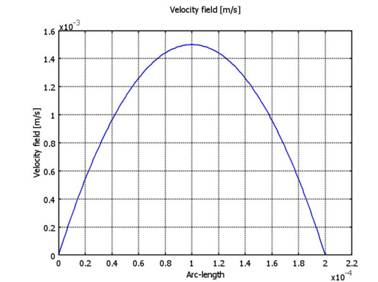

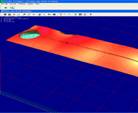

Fluid

flow through the microfluidic channel was performed using the specialized

simulation software COMSOL. The simu-lations were performed to determine the

velocity field of the fluid in absence of electrical field. To

determine this parameter is very important

because it is involved in determination of fluid

debit. In this simulation the flow was considered to be laminarn and incompressible. Therefore, the simulations were done

using the application mode "General laminar flow"

that uses the Navier-Stokes model for fluid

flow. The pressure at the inlet of the microchannel

was considered to be 20 Pa s. Since the concentration of the nanoparticles is very low we can consider that the

fluid in this simulation has physical

parameters of water, with a density of 1000

kg/m3 and the dynamic viscosity of 10 Pa

s.

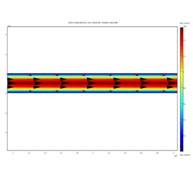

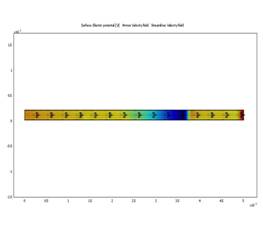

Fig. 7 presents the simulation results for the

velocity field of the fluid in a section parallel

in the plane xOy. We can see a constant flow in the channel.

Fig. 7. Velocity field

in the microchannel.

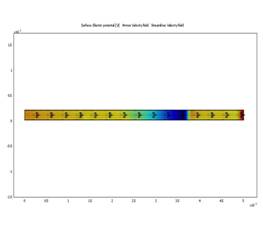

Simulations of electrokinetic flow through a 2D

microchannel have been performed using the Electroosmotic Flow Mode of the

COMSOL simulation software. We considered in simulations a channel length of

8520µm and a channel width of 200µm. An electric potential of 2.5V is applied

on the electrodes placed under the microfluidic channel. A coupled domain

simulation has been performed. First it is solved the problem in the Conductive

Media Domain and the distribution of the electric field generated in the

microchannel is determined. Fig. 8 presents variation of the electric potential

along the microchannel after the activation of the electrodes.

Fig. 8. Electric

potential along the microchannel after the activation of the electrodes.

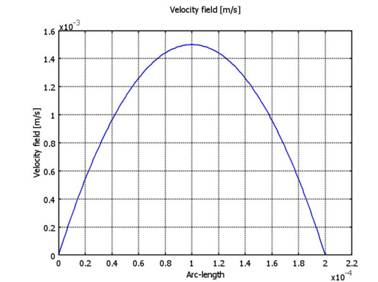

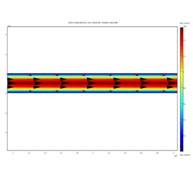

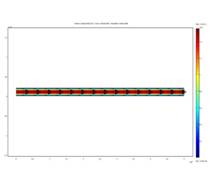

The second step of the simulation consists in the

solving the Stokes Flow problem to determine the movement of the fluid through

the microchannel. Fig. 9 presents the velocity field in the channel under the

influence of the electric potential. The fluid that flowsthrough the

microfluidic channel is an aqueous solutions with suspended magnetic

nanoparticles. The simulation showed that the maximum value of the fluid

velocity in the channel is 1.53 mm/s.

a) b)

b)

Fig. 9. Velocity

field in the microchannel under the influence of the electrostatic field: (a)

general view; (b) close up.

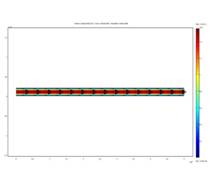

The

diffusivity of the suspended nanoparticles is 0.2 m2/s

and the concentration at the channel inlet is 0.1 mol/m3. Fig. 9

presents the velocity graph in the transversal section in the middle portion of

the channel (Fig. 10).

Fig.

10. Velocity of the fluid in the transversal section in the

middle portion of the channel.

5. Conclusions

Magnetite solutions functionalized with various metals

have been were prepared, characterized and tested. We manufacture a

microfluidic device using SU-8 polymer material and gold electrodes in order to

observe the behavior of the magnetite solutions. The magnetite nanoparticles

(simple or functionalized) in solution presented an agglomerations and formed

crystals with different sizes (SEM investigations). Special property of

magnetite fluids is a combination of normal liquid behavior and magnetic

control of position and flow. The microfluidic system was characterized with

different techniques: SEM, FTIR and white light interferometry. It was observed

that particles in aqueous solution have a controlled movement from the inlet

reservoir to the outlet reservoir, under direct or in reversed polarization.

The simulations of the liquid flow within the microchannel were performed using

COMSOL Multiphysics software, in order to calculate the fluid velocity. Due to

their physical, chemical, mechanical and thermal properties the nanoparticles

obtained we shall use our device in further work regarding bio-applications.

References

[1]

C. Rinaldi, T. Franklin, M. Zahn, T. Cader, Encyclopedia of Nanoscience and

Nanotechnology,

2004.

[2]

X.-C. Shen, X.-Z. Fang, Y.-H. Zhou, H. Liang, Chem. Lett. 11 (2004) 1468.

[3]

E.I. Friedmann, J. Wicrzchos, C. Ascaso, M. Winklhofer, Proc. Natl. Acad. Sci.

U.S.A.

98 (2001) 2176.

[4]

K.L. Thomas-Keprta, D.A. Bazylinscki, J.L. Kirschvink, S.J. Clemett, D.S.

McKAY, S.J. Wentworth, H. Vali, E.K. Gibson, C.S. Romanek, Geochim. Cosmochim.

Acta 64 (2000) 4049.

[5]

T. Schneider, L.R. Moore, Y. Jing, S. Haam, P.S. Williams, A.J. Fleischman, S.

Roy, J.J. Chalmers, M. Zborowski, J. Biochem. Biophys. Methods (2006) 68.

[6]

K.E. McCloskey, J. Chalmers, M. Zborowski, Anal. Chem. (2003) 75.

[7]

L.X. Tiefenauer, A. Tschirky, G. Kuhne, R. Andres, Magn. Reson. Imaging 14 (4)

(1996).

[8]

R. Kopelmana, Y.L. Koo, M. Philbert, B.A. Moffat, G.R. Reddy, P. McConville,

D.E. Hall, T.L. Chenevert, M.S. Bhojani, S.M. Buck, A. Rehentulla, B.D. Ross,

J. Magn. Magn. Mater. 293 (2005) 404.

[9]

J. Yang, S.-B. Park, H.-G. Yoon, Y.-M. Huh, S. Haam, Int. J. Pharma 324 (2006)

185.

[10]

V. Cabuil, Encyclopedia of Surface and Colloid Science, Marcel-Dekker Inc., New

York, 2002, pp. 4306.

[11]

A.S.G. Berry, J. Curtis, Phys. D.: Appl. Phys. (2003) 36.

[12]

B.S. Lee, T.C. Strand, Appl. Optics 29 (1990) 3784-3788.

[13]

T. Dresel, G. Häusler, H. Venzke, Appl. Optics 31 (7) (1992) 915-919.

b)

b)

c)

c)

b)

b)

b)

b)